Automated Production Systems Implementation Guide

Modern manufacturing demands efficiency, precision, and cost-effectiveness to remain competitive in today's global market. Automated production systems, particularly in welding operations, have revolutionized how manufacturers approach their production processes. These systems integrate advanced robotics, artificial intelligence, and sophisticated control mechanisms to deliver consistent, high-quality results while reducing labor costs and production time. For Kenyan manufacturers looking to modernize their operations, understanding the implementation process of automated welding systems is crucial for staying ahead in the industrial landscape.

2025 Production Guide: Strategic Planning for Automation

Implementing automated production systems requires careful strategic planning and assessment of current manufacturing capabilities. Companies must evaluate their production volumes, quality requirements, and available resources before committing to automation investments. The planning phase involves analyzing workflow patterns, identifying bottlenecks, and determining which processes would benefit most from automation. Successful implementation begins with setting clear objectives, establishing realistic timelines, and securing adequate funding for both equipment and training.

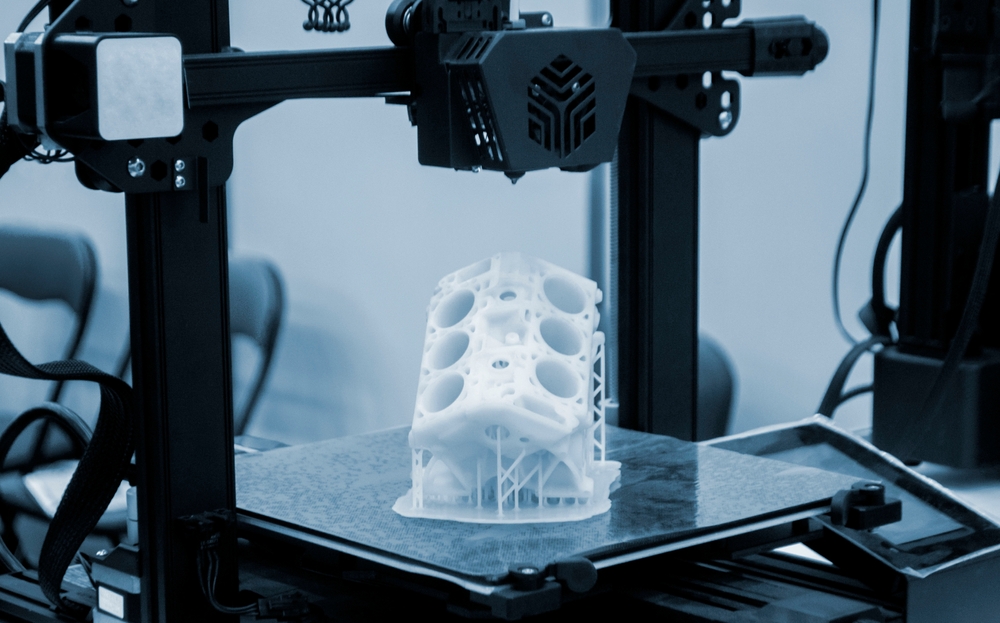

How to Integrate Fully Automatic Welding for Better Efficiency

Integrating fully automatic welding systems involves several critical steps that ensure seamless operation and maximum efficiency gains. The process starts with selecting appropriate welding equipment that matches specific production requirements, including material types, joint configurations, and production volumes. System integration requires careful coordination between robotic welding units, material handling systems, and quality control mechanisms. Programming and calibration of automated welding systems demand expertise in both welding technology and robotics, making proper training essential for operational staff.

Equipment Selection and Technical Specifications

Choosing the right automated welding equipment depends on various factors including material compatibility, production capacity, and precision requirements. Modern automated welding systems offer different technologies such as MIG, TIG, and laser welding capabilities, each suited for specific applications. Technical specifications to consider include welding speed, penetration depth, heat-affected zone control, and repeatability accuracy. The selection process should also account for maintenance requirements, spare parts availability, and technical support accessibility in the Kenyan market.

Workforce Training and Skill Development

Successful automation implementation requires comprehensive workforce training programs that prepare employees for new operational roles. Traditional welders need retraining to operate and monitor automated systems, while maintenance staff must develop skills in robotics and control systems. Training programs should cover system operation, troubleshooting procedures, preventive maintenance, and safety protocols. Investing in employee development ensures smooth transition periods and maximizes the long-term benefits of automation investments.

Quality Control and Monitoring Systems

Automated welding systems incorporate advanced quality control mechanisms that continuously monitor weld quality and process parameters. These systems use sensors, cameras, and measurement devices to detect defects in real-time, allowing for immediate corrections and reducing waste. Implementing comprehensive monitoring systems provides valuable data for process optimization and helps maintain consistent quality standards. Quality control integration also enables predictive maintenance scheduling and performance analysis for continuous improvement initiatives.

Cost Analysis and Implementation Comparison

Understanding the financial implications of automated welding system implementation is crucial for making informed investment decisions. The following comparison provides insights into typical cost structures and provider options available in the market.

| System Type | Provider | Cost Estimation |

|---|---|---|

| Basic Robotic Welding Cell | KUKA Robotics | KSh 10,400,000 - KSh 19,500,000 |

| Advanced Multi-Station System | ABB Robotics | KSh 26,000,000 - KSh 52,000,000 |

| Custom Automated Line | Fanuc Corporation | KSh 39,000,000 - KSh 104,000,000 |

| Compact Welding Robot | Universal Robots | KSh 6,500,000 - KSh 15,600,000 |

| Laser Welding System | IPG Photonics | KSh 32,500,000 - KSh 78,000,000 |

Prices, rates, or cost estimates mentioned in this article are based on the latest available information but may change over time. Independent research is advised before making financial decisions.

Implementation costs vary significantly based on system complexity, customization requirements, and installation specifications. Additional expenses include training costs, facility modifications, and ongoing maintenance contracts. Return on investment calculations should consider labor savings, quality improvements, and increased production capacity over the system’s operational lifetime.

Maintenance and Long-term Sustainability

Maintaining automated welding systems requires structured preventive maintenance programs and skilled technical support. Regular maintenance schedules help prevent unexpected downtime and extend equipment lifespan, while proper documentation ensures consistent service quality. Establishing relationships with reliable service providers and maintaining adequate spare parts inventory are essential for sustained operations. Long-term sustainability also depends on staying updated with technological advances and planning for future system upgrades as production requirements evolve.