Understanding 3D Printers: Technology, Applications and Future Potential

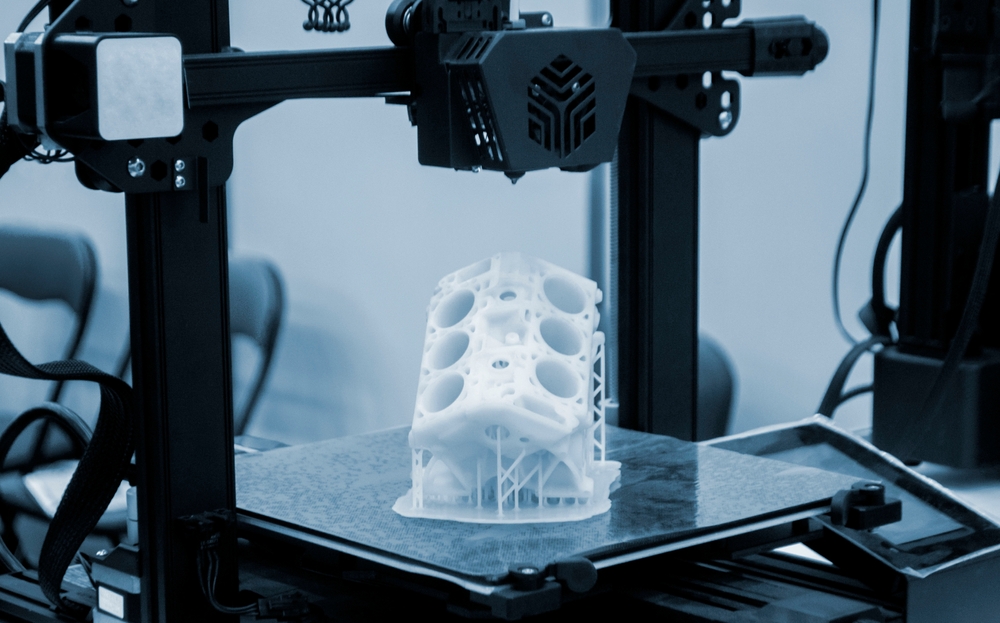

3D printing technology has revolutionized manufacturing across industries by enabling the creation of three-dimensional objects from digital designs. This additive manufacturing process builds objects layer by layer, allowing for complex geometries that traditional manufacturing methods cannot achieve. From rapid prototyping to custom medical implants, 3D printing continues to expand possibilities for creators, businesses, and researchers alike.

3D printing technology represents one of the most significant manufacturing innovations of the 21st century. Unlike traditional subtractive manufacturing that removes material to create objects, 3D printing builds objects layer by layer using various materials including plastics, metals, ceramics, and even biological materials. This additive approach allows for unprecedented design freedom, reduced material waste, and the ability to create complex geometries that would be impossible with conventional manufacturing techniques.

How Do 3D Printers Work?

3D printing begins with a digital 3D model, typically created using Computer-Aided Design (CAD) software or generated through 3D scanning. This model is then processed by slicing software that converts the 3D model into thin horizontal layers and generates instructions (G-code) for the printer to follow. The printer reads these instructions and builds the object layer by layer according to the specified design.

Different 3D printing technologies employ various methods for creating these layers. Fused Deposition Modeling (FDM) extrudes melted thermoplastic through a nozzle, while Stereolithography (SLA) uses a laser to cure liquid resin. Selective Laser Sintering (SLS) fuses powder particles together, and Digital Light Processing (DLP) uses a digital light projector to cure entire layers at once. Each technology offers distinct advantages in terms of resolution, material options, speed, and cost.

Types of 3D Printers for Different Applications

The 3D printing ecosystem encompasses a wide range of printer types designed for specific applications and user requirements. Consumer-grade FDM printers, typically priced between €200 and €1,000, offer an accessible entry point for hobbyists and educational settings. These machines primarily work with thermoplastics like PLA and ABS, suitable for basic prototypes and small projects.

Professional-grade printers, ranging from €2,000 to €20,000, deliver higher precision, reliability, and material versatility. These systems cater to small businesses, design studios, and engineering departments for functional prototyping and small-batch production. Industrial 3D printers, which can cost anywhere from €50,000 to several million euros, represent the high end of the market with capabilities for metal printing, large-scale production, and specialized applications in aerospace, automotive, and medical industries.

Materials Used in 3D Printing

The range of materials compatible with 3D printing continues to expand, driving new applications across industries. Standard thermoplastics like PLA offer biodegradability and ease of use, while ABS provides greater durability and heat resistance. Engineering-grade materials such as nylon, PETG, and TPU deliver specialized properties including flexibility, chemical resistance, and strength.

Metal 3D printing, using materials like stainless steel, titanium, and aluminum alloys, has revolutionized manufacturing for aerospace, automotive, and medical applications. These materials enable the creation of lightweight yet strong components with complex internal structures. Additionally, specialized materials including ceramics, composites, and biocompatible resins are expanding the boundaries of what can be produced using additive manufacturing technologies.

Industry Applications and Impact

3D printing has transformed numerous industries by enabling new approaches to design, manufacturing, and supply chain management. In healthcare, the technology produces patient-specific surgical guides, anatomical models for surgical planning, and custom prosthetics and implants. The aerospace industry leverages 3D printing for lightweight components with complex geometries that reduce fuel consumption and improve performance.

Manufacturing benefits from rapid prototyping capabilities that accelerate product development cycles while reducing costs. Architecture firms use 3D printing to create detailed models and even full-scale building components. In education, 3D printers serve as powerful teaching tools for STEM subjects, allowing students to bring their designs to life. The technology has also found applications in fashion, jewelry, food production, and humanitarian aid for on-demand manufacturing of critical supplies in remote locations.

Comparison of Popular 3D Printer Models

When selecting a 3D printer, consumers and businesses must consider various factors including printing technology, build volume, resolution, and material compatibility. The market offers options across price points and capability levels.

| Printer Model | Technology | Build Volume | Resolution | Price Range |

|---|---|---|---|---|

| Prusa i3 MK3S+ | FDM | 250 x 210 x 210 mm | 0.05 mm | €750-€1,000 |

| Creality Ender 3 V2 | FDM | 220 x 220 x 250 mm | 0.1 mm | €200-€300 |

| Formlabs Form 3 | SLA | 145 x 145 x 185 mm | 0.025 mm | €3,500-€4,000 |

| Ultimaker S5 | FDM | 330 x 240 x 300 mm | 0.02 mm | €5,500-€6,500 |

| Markforged Mark Two | FDM | 320 x 132 x 154 mm | 0.1 mm | €13,000-€17,000 |

Prices, rates, or cost estimates mentioned in this article are based on the latest available information but may change over time. Independent research is advised before making financial decisions.

Future Trends in 3D Printing Technology

The 3D printing industry continues to evolve rapidly, with several emerging trends poised to expand its capabilities and applications. Multi-material printing represents a significant advancement, allowing for the creation of objects with varying material properties in a single print. This capability enables the production of components with integrated circuits, varying densities, or combined rigid and flexible sections.

Speed improvements remain a focus area for manufacturers, with new technologies promising to reduce print times from hours to minutes. Continuous liquid interface production (CLIP) and high-speed sintering are among the methods being developed to address this limitation. Additionally, larger build volumes are becoming available, allowing for the printing of bigger objects or more parts simultaneously.

Sustainability initiatives are driving innovation in recycled and bio-based printing materials, reducing the environmental impact of 3D printing. Meanwhile, advancements in software are making the technology more accessible through simplified design tools, automated support generation, and improved slicing algorithms that optimize print quality and efficiency.

As these technologies mature, 3D printing will likely continue its transition from primarily prototyping applications to end-use production across more industries. The combination of design freedom, customization capabilities, and increasingly competitive economics positions additive manufacturing as a transformative force in how we conceptualize, design, and produce objects in the coming decades.