Why Electronic Testing Prevents Product Failures

Product failures can devastate businesses, damage reputations, and pose serious safety risks to consumers. Electronic testing serves as a critical safeguard in the development and manufacturing process, identifying potential issues before products reach the market. Through comprehensive testing protocols, manufacturers can ensure their electronic devices meet safety standards, perform reliably under various conditions, and deliver the quality consumers expect.

Modern electronic devices are integral to virtually every aspect of daily life, from smartphones and laptops to medical equipment and automotive systems. The complexity of these devices means that even minor flaws can lead to catastrophic failures, making rigorous testing essential for product success and consumer safety.

How Equipment Testing Keeps Products Safe, Reliable, and Ready

Electronic testing encompasses a wide range of procedures designed to verify that products meet specified requirements and industry standards. Safety testing ensures devices won’t pose electrical hazards, fire risks, or other dangers to users. Reliability testing subjects products to stress conditions, temperature variations, and extended use scenarios to predict long-term performance. Functional testing verifies that all features work as intended across different operating environments.

These testing protocols help manufacturers identify design flaws, component weaknesses, and manufacturing defects before products reach consumers. By catching issues early, companies can make necessary adjustments, preventing costly recalls and protecting their reputation.

Why Equipment Testing Matters for Business Success

The financial implications of inadequate testing can be severe. Product recalls can cost millions of pounds, while liability claims from faulty products can devastate smaller companies. Beyond immediate costs, failed products damage brand trust and market position, effects that can persist for years.

Testing also ensures compliance with regulatory requirements. In the UK, electronic products must meet specific safety and electromagnetic compatibility standards before they can be sold. Failure to comply can result in products being banned from the market, fines, and legal consequences.

Moreover, thorough testing provides competitive advantages. Products that consistently perform well build customer loyalty and positive reviews, leading to increased market share and profitability.

Getting Insights on Electronic Test Equipment

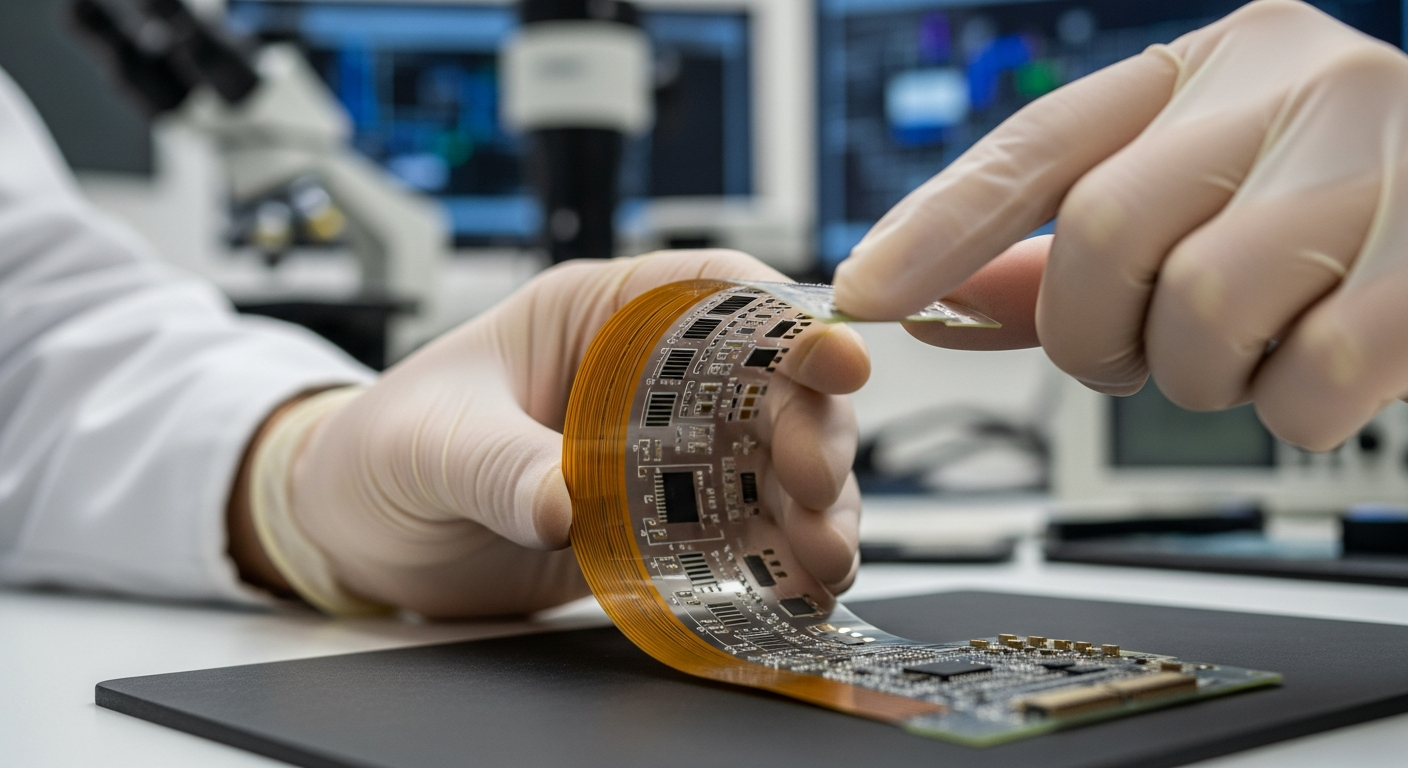

Modern test equipment provides manufacturers with detailed insights into product performance and potential failure modes. Oscilloscopes analyse electrical signals, spectrum analysers examine frequency responses, and environmental chambers simulate extreme conditions. Advanced automated test equipment can run thousands of tests simultaneously, providing comprehensive data on product behaviour.

This equipment generates valuable data that helps engineers understand how products perform under various conditions. Thermal imaging cameras reveal heat distribution patterns, while vibration analysers identify mechanical stress points. This information guides design improvements and helps predict maintenance requirements.

Types of Electronic Testing Methods

Functional testing verifies that products operate according to specifications under normal conditions. Environmental testing exposes devices to temperature extremes, humidity, vibration, and other stress factors. Electromagnetic compatibility testing ensures devices don’t interfere with other electronics and can operate in electromagnetic environments.

Accelerated life testing subjects products to intensified stress conditions to predict long-term reliability in compressed timeframes. This approach helps manufacturers estimate product lifespan and identify components likely to fail first.

Real-World Testing Solutions and Providers

| Provider | Services Offered | Key Features |

|---|---|---|

| Keysight Technologies | Comprehensive electronic testing solutions | Advanced measurement equipment, software integration |

| Rohde & Schwarz | RF and wireless testing equipment | High-precision instruments, regulatory compliance testing |

| National Instruments | Automated test systems | Modular platforms, custom test development |

| Tektronix | Signal analysis and measurement | Oscilloscopes, spectrum analysers, protocol analysers |

| Element Materials Technology | Independent testing services | Environmental testing, regulatory compliance, certification |

The Future of Electronic Testing

Emerging technologies are transforming electronic testing approaches. Artificial intelligence and machine learning algorithms can predict failure modes and optimise testing procedures. Internet of Things devices enable continuous monitoring of products in real-world environments, providing ongoing performance data.

Virtual testing using computer simulations is becoming increasingly sophisticated, allowing engineers to identify potential issues before physical prototypes are built. This approach reduces development time and costs while improving product quality.

Electronic testing remains fundamental to product development success. As devices become more complex and consumer expectations continue to rise, comprehensive testing protocols become increasingly critical. Companies that invest in thorough testing processes protect themselves from costly failures while building reputations for quality and reliability. The integration of advanced testing equipment and methodologies ensures that electronic products meet the demanding requirements of modern applications while maintaining the safety and performance standards consumers deserve.