Understanding Additive Manufacturing Technology and Applications

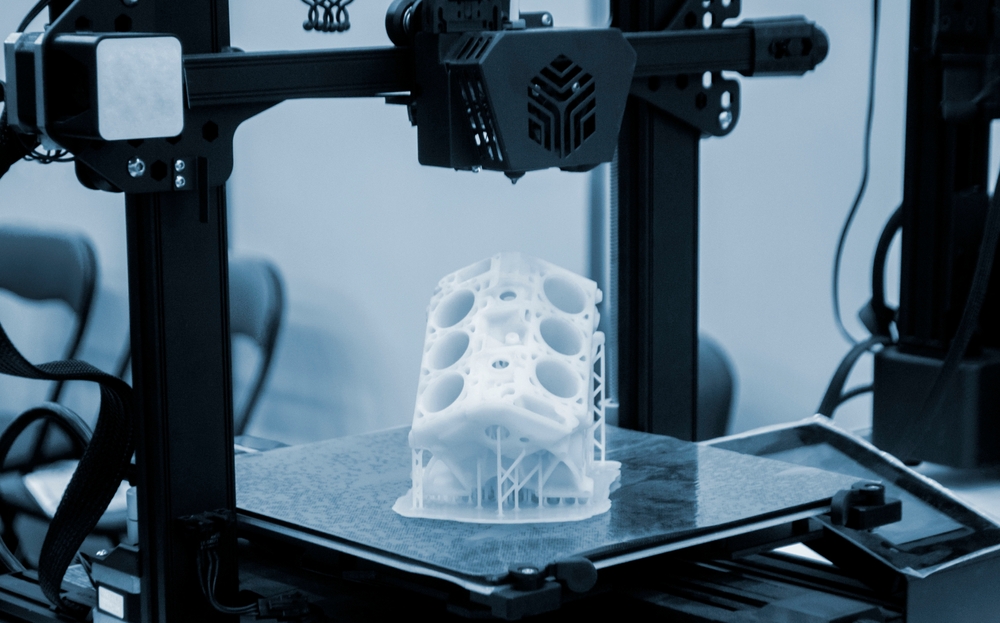

Additive manufacturing technology has revolutionized production processes across industries by enabling the creation of three-dimensional objects from digital designs. This layer-by-layer building approach offers unprecedented flexibility in prototyping, customization, and small-scale production that traditional manufacturing methods cannot match.

Additive manufacturing technology has transformed how we conceptualize, design, and create objects across numerous industries. Unlike traditional manufacturing that typically removes material to create shapes, this technology builds objects additively, layer by layer, directly from digital models. This revolutionary approach allows for complex geometries, rapid prototyping, and customized production that would be impossible or prohibitively expensive with conventional methods. As the technology continues to mature and become more accessible, understanding its capabilities, limitations, and applications becomes increasingly valuable for businesses and individuals alike.

How Additive Manufacturing Works

This technology operates on a fundamental principle: creating physical objects by depositing material layer upon layer according to a digital blueprint. The process begins with a 3D model created in computer-aided design (CAD) software or obtained from 3D scanning. This model is then processed through slicing software that converts it into thin horizontal layers and generates instructions (G-code) for the machine to follow. Different printing technologies exist, with Fused Deposition Modeling (FDM) being the most common for consumer devices. FDM works by extruding heated thermoplastic filament through a nozzle that moves precisely along predetermined paths, building the object from the bottom up. Other technologies include Stereolithography (SLA), which uses light to cure liquid resin, and Selective Laser Sintering (SLS), which fuses powder materials using lasers.

Types of Materials Used

The versatility of additive manufacturing stems largely from the wide range of available materials. For FDM machines, common filaments include PLA (Polylactic Acid), a biodegradable plastic ideal for beginners due to its ease of use; ABS (Acrylonitrile Butadiene Styrene), known for durability but requiring higher temperatures; and PETG, which combines strength with flexibility. More specialized materials include TPU for flexible prints, nylon for strong mechanical parts, and composite filaments infused with wood, metal, or carbon fiber. Resin-based systems use photopolymers that vary in properties from standard resins to engineering-grade materials, dental resins, and castable options. Industrial machines can work with metal powders including aluminum, titanium, and stainless steel, as well as ceramics and even concrete for construction applications.

Applications Across Industries

The impact of this technology spans virtually every sector. In manufacturing, it enables rapid prototyping, reducing development cycles from months to days by allowing designers to quickly iterate physical models. Healthcare has embraced the technology for producing anatomical models for surgical planning, custom prosthetics, and even bioprinting of tissues and organs. The aerospace industry uses additive manufacturing to create lightweight components with complex geometries that reduce fuel consumption. Automotive manufacturers print custom parts and tooling for production lines. Architecture firms print detailed models of buildings and urban developments. In education, these machines serve as powerful teaching tools for STEM subjects. Even fashion designers experiment with printed textiles and accessories, while the food industry explores creating edible creations with specialized food printers.

Consumer vs. Professional Equipment

The market spans from entry-level consumer devices to sophisticated industrial machines. Consumer models typically use FDM technology, offering build volumes around 200-300mm cubic and resolution down to 100 microns. They’re designed with user-friendly interfaces, require minimal maintenance, and typically cost between $200-$1,000. Professional-grade equipment offers larger build volumes, finer resolution (down to 25 microns), higher precision, and support for advanced materials. These systems, ranging from $2,000 to $10,000, feature enclosed build chambers, heated beds, and multiple extruders. Industrial machines represent the high end of the spectrum, with prices from $50,000 to several million dollars. They offer unparalleled precision, reliability, and material capabilities, including metal printing, and are designed for continuous production environments with sophisticated monitoring systems.

Comparing Popular Models and Brands

The market offers options for every skill level and application. Here’s a comparison of some notable models across different categories:

| Model | Technology | Build Volume | Resolution | Price Range |

|---|---|---|---|---|

| Creality Ender 3 V2 | FDM | 220x220x250mm | 100 microns | $250-$300 |

| Prusa i3 MK3S+ | FDM | 250x210x210mm | 50 microns | $750-$1,000 |

| Elegoo Mars 2 Pro | MSLA (Resin) | 129x80x160mm | 50 microns | $250-$300 |

| Formlabs Form 3 | SLA (Resin) | 145x145x185mm | 25 microns | $3,500-$4,000 |

| Ultimaker S5 | FDM | 330x240x300mm | 20 microns | $5,995-$6,500 |

| Markforged Mark Two | FDM (Composite) | 320x132x154mm | 100 microns | $13,500-$15,000 |

| EOS M 290 | DMLS (Metal) | 250x250x325mm | 40 microns | $200,000+ |

Prices, rates, or cost estimates mentioned in this article are based on the latest available information but may change over time. Independent research is advised before making financial decisions.

Software and Design Considerations

Successful additive manufacturing requires mastery of both hardware and software. The process begins with 3D modeling software, ranging from beginner-friendly options like Tinkercad and Fusion 360 to professional tools like SolidWorks and Blender. Once a model is created, slicing software prepares it for printing by converting the 3D model into machine instructions. Popular slicing programs include Cura, PrusaSlicer, and Simplify3D, each offering different features for optimizing print settings. Design considerations are crucial for successful prints: models must account for the limitations of the printing process, including minimum feature sizes, overhang angles, and support structures. Orientation affects both print quality and strength, while infill percentage balances between material usage and structural integrity. Understanding these parameters allows designers to optimize their models for successful printing, minimizing failures and achieving the desired results.

The Future of Additive Manufacturing

The trajectory of this technology points toward increasing accessibility, capability, and integration with other technologies. Material science advances continue to expand the range of printable substances, including multi-material printing that combines different properties in a single print. Speed improvements are addressing one of the technology’s main limitations, with new approaches like continuous liquid interface production (CLIP) dramatically reducing print times. Metal printing is becoming more affordable, potentially revolutionizing manufacturing of complex metal parts. Integration with artificial intelligence is optimizing parameters and predicting failures before they occur. Perhaps most exciting is the development of large-scale construction printers capable of building houses and infrastructure components, and bioprinting research that aims to produce functional human organs. As these technologies mature, additive manufacturing will likely transition from primarily a prototyping tool to a mainstream production method for end-use products.