Understanding 3D Printing Technology: How It Works and Applications

3D printing has revolutionized manufacturing by enabling the creation of three-dimensional objects from digital designs. This additive manufacturing process builds objects layer by layer, offering unprecedented flexibility in prototyping and production. From healthcare to aerospace, 3D printing continues to transform industries with its ability to create complex structures that were previously impossible or prohibitively expensive to manufacture.

3D printing technology has transformed the manufacturing landscape, allowing users to create physical objects directly from digital designs. Unlike traditional manufacturing that removes material to shape objects, 3D printing builds items layer by layer, offering unprecedented flexibility and efficiency. This technology has evolved from simple plastic prototyping to creating functional parts in materials ranging from polymers to metals and even biological tissues, making it increasingly accessible to businesses, educators, and hobbyists alike.

How 3D Printers Work

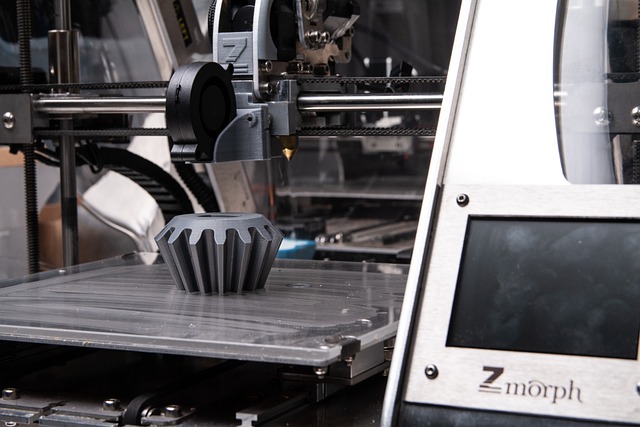

3D printing begins with a digital 3D model, typically created in Computer-Aided Design (CAD) software or captured through 3D scanning. This model is then processed by slicing software, which converts the 3D model into horizontal layers and generates instructions for the printer to follow. The printer then builds the object layer by layer according to these instructions. Different printing technologies use various methods for this process - Fused Deposition Modeling (FDM) extrudes melted material through a nozzle, while Stereolithography (SLA) uses light to cure liquid resin. Each printing method offers distinct advantages in terms of resolution, material compatibility, and production speed.

Types of 3D Printing Technologies

Several 3D printing technologies have emerged over the years, each with specific applications and benefits. FDM printers are the most common and affordable, making them popular for home and educational use. These printers heat plastic filament and deposit it in precise patterns. SLA printers use lasers or projected light to cure liquid resin, producing highly detailed objects ideal for jewelry, dental applications, and detailed prototypes. Selective Laser Sintering (SLS) uses lasers to fuse powdered materials like nylon or metal, creating durable functional parts. Direct Metal Laser Sintering (DMLS) specializes in metal printing for aerospace, automotive, and medical applications. The technology continues to evolve with multi-material and multi-color printing capabilities becoming increasingly available.

Materials Used in 3D Printing

The range of materials compatible with 3D printers has expanded dramatically. Standard filaments include PLA (Polylactic Acid), a biodegradable material derived from renewable resources like corn starch, making it environmentally friendly and easy to print. ABS (Acrylonitrile Butadiene Styrene) offers greater durability and heat resistance but requires ventilation during printing. PETG combines the ease of printing of PLA with improved durability. More specialized materials include flexible filaments like TPU for rubber-like objects, wood-infused filaments that can be sanded and stained, and metal-infused filaments that provide metallic properties. Professional printers can work with photopolymer resins, nylon powders, and even direct metal printing with aluminum, titanium, and stainless steel alloys.

Industrial Applications

3D printing has revolutionized numerous industries by enabling rapid prototyping, custom manufacturing, and complex geometries impossible with traditional methods. In aerospace, companies print lightweight components that reduce fuel consumption and carbon emissions. The automotive industry utilizes 3D printing for both prototyping and end-use parts in high-performance vehicles. Medical applications include patient-specific surgical guides, anatomical models for surgical planning, and even bioprinting of tissues and organs. Architecture firms create detailed scale models of buildings and structures. The technology also enables on-demand manufacturing of replacement parts, reducing inventory costs and addressing supply chain challenges by allowing production closer to the point of use.

Consumer and Educational Uses

The accessibility of 3D printers has expanded their use beyond industrial applications. Home users create custom household items, replacement parts, and decorative objects. Educators incorporate 3D printing into STEM curriculum, helping students understand design principles, engineering concepts, and manufacturing processes through hands-on learning. Makers and hobbyists use 3D printers to bring creative projects to life, from custom game pieces to intricate art installations. Libraries and community makerspaces often provide access to 3D printers, democratizing this technology for wider public use. The educational benefits extend to developing spatial reasoning, problem-solving skills, and an understanding of digital design that prepares students for future careers in technology and engineering.

3D Printer Market and Cost Considerations

The 3D printer market offers options ranging from entry-level consumer models to industrial-grade systems. Consumer-level printers have become increasingly affordable while offering improved reliability and print quality. For those considering a 3D printer purchase, understanding the available options and their associated costs is essential.

| Printer Category | Price Range | Features | Best For |

|---|---|---|---|

| Entry-Level FDM | $200-$500 | Single extruder, small build volume, basic materials | Beginners, hobbyists, education |

| Mid-Range FDM | $500-$2,500 | Larger build volume, dual extruders, heated beds | Serious hobbyists, small businesses |

| Professional FDM | $2,500-$10,000 | Enclosed chambers, multiple materials, high precision | Professional prototyping, small production runs |

| Entry-Level Resin (SLA/DLP) | $300-$800 | Small build volume, high detail | Jewelry, dental, detailed miniatures |

| Professional Resin | $3,000-$10,000 | Larger build volume, higher precision, faster printing | Professional modeling, dental, jewelry |

| Industrial Systems | $20,000-$100,000+ | Metal printing, large format, high throughput | Manufacturing, aerospace, medical |

Prices, rates, or cost estimates mentioned in this article are based on the latest available information but may change over time. Independent research is advised before making financial decisions.

Beyond the initial printer purchase, ongoing costs include materials (filament or resin), maintenance parts like nozzles and build surfaces, and potential software subscriptions. Entry-level filament typically costs $20-$50 per kilogram, while specialty filaments can cost $50-$100 or more. Resin prices range from $40-$200 per liter depending on properties and applications.

Future Trends in 3D Printing

The 3D printing landscape continues to evolve rapidly with several emerging trends. Speed improvements are addressing one of the technology’s primary limitations, with new techniques reducing print times from hours to minutes. Material science advancements are expanding the range of printable substances, including composites with enhanced properties, sustainable bio-based materials, and conductive filaments for electronic applications. Multi-material printing capabilities are growing, allowing single prints to combine rigid and flexible components or multiple colors without assembly. Large-format printers are enabling construction applications, with companies demonstrating the ability to print concrete structures and houses. Perhaps most promising is the continued development of bioprinting, where researchers are making progress toward printing functional organs using living cells, potentially revolutionizing transplant medicine and reducing organ shortages.

As costs decrease and capabilities increase, 3D printing continues its transition from a prototyping technology to a viable manufacturing method for end-use products across numerous industries. The democratization of this technology empowers innovation at all levels, from individual creators to global enterprises, fundamentally changing how we design, produce, and distribute physical goods.