Understanding 3D Printing Technology and Applications

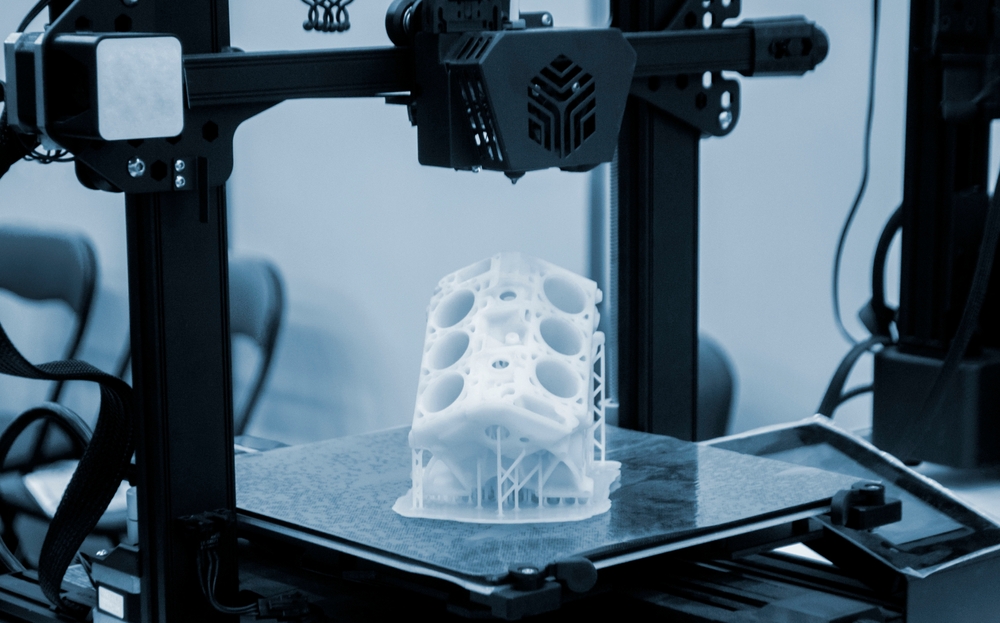

Three-dimensional printing has revolutionized manufacturing, prototyping, and creative industries by transforming digital designs into physical objects layer by layer. This innovative technology uses various materials and methods to create everything from simple household items to complex medical devices, making it accessible to both professionals and hobbyists seeking to bring their ideas to life.

The world of three-dimensional manufacturing has experienced remarkable growth, with printing technologies becoming increasingly sophisticated and accessible. Modern printer systems can work with plastics, metals, ceramics, and even biological materials, opening possibilities that were unimaginable just decades ago.

How Does Printer Technology Work?

Three-dimensional printing operates through additive manufacturing, where materials are deposited layer by layer to build objects from digital blueprints. The process begins with a computer-aided design file that gets sliced into thousands of horizontal cross-sections. The printer then follows these instructions, precisely placing material according to each layer’s specifications. Common printing methods include fused deposition modeling, stereolithography, and selective laser sintering, each offering unique advantages for different applications and materials.

Types of Printing Materials and Methods

Various printing technologies cater to different needs and budgets. Fused deposition modeling uses thermoplastic filaments heated and extruded through a nozzle, making it popular for beginners and educational settings. Stereolithography employs liquid resin cured by ultraviolet light, producing highly detailed objects with smooth surfaces. Selective laser sintering uses powdered materials fused by laser energy, enabling the creation of complex geometries without support structures. Each method has distinct material requirements, from basic PLA plastic to advanced metal powders and biocompatible resins.

Applications Across Industries

Printing technology serves numerous sectors, from aerospace and automotive to healthcare and education. Medical professionals use bioprinters to create prosthetics, dental implants, and even tissue scaffolds for regenerative medicine. Aerospace companies leverage metal printing for lightweight, complex components that traditional manufacturing cannot produce. Architects and designers create detailed models and prototypes, while educators use classroom printers to make learning more interactive and engaging. The automotive industry employs this technology for rapid prototyping and custom tooling.

Cost Considerations and Market Options

The printing market offers solutions ranging from budget-friendly desktop models to industrial-grade systems. Entry-level consumer printers typically cost between $200 and $800, suitable for hobbyists and small projects. Professional desktop models range from $1,000 to $5,000, offering better precision and material compatibility. Industrial systems can cost $50,000 to $500,000 or more, depending on size, materials, and capabilities.

| Printer Category | Price Range | Typical Applications |

|---|---|---|

| Entry-Level Consumer | $200 - $800 | Hobby projects, education, simple prototypes |

| Professional Desktop | $1,000 - $5,000 | Small business, detailed prototypes, jewelry |

| Industrial Systems | $50,000 - $500,000+ | Manufacturing, aerospace, medical devices |

Prices, rates, or cost estimates mentioned in this article are based on the latest available information but may change over time. Independent research is advised before making financial decisions.

Choosing the Right Printing Solution

Selecting appropriate printing equipment depends on intended use, budget, and technical requirements. Beginners should consider factors like ease of use, available support, and material costs. Print volume, resolution requirements, and material compatibility become crucial for professional applications. Software compatibility, maintenance needs, and upgrade possibilities also influence long-term satisfaction. Many manufacturers offer trial programs or demonstrations, allowing potential users to evaluate capabilities before purchasing.

Future Developments in Printing Technology

The printing industry continues evolving with advances in materials science, software capabilities, and hardware precision. Researchers are developing new printable materials including conductive inks, biodegradable plastics, and composite materials with enhanced properties. Multi-material printing systems enable objects with varying characteristics within single builds. Speed improvements and larger build volumes make the technology more practical for production applications. Integration with artificial intelligence and machine learning promises automated optimization and quality control, making printing more accessible and reliable for various users and applications.