Understanding 3D Printers: Technology, Applications, and Options

3D printing technology has revolutionized manufacturing, prototyping, and creative design across industries. These versatile machines transform digital designs into physical objects layer by layer, opening new possibilities for businesses, educators, hobbyists, and medical professionals. As the technology becomes more accessible, understanding the fundamentals of 3D printing can help users select the right equipment for their specific needs.

3D printing has transformed from an industrial curiosity into a mainstream technology that’s reshaping how we design, manufacture, and conceptualize physical objects. These remarkable machines build three-dimensional objects by depositing materials layer by layer according to precise digital instructions. From rapid prototyping in engineering to customized medical implants, 3D printers have expanded what’s possible across countless fields while becoming increasingly accessible to everyday users.

How Do 3D Printers Work?

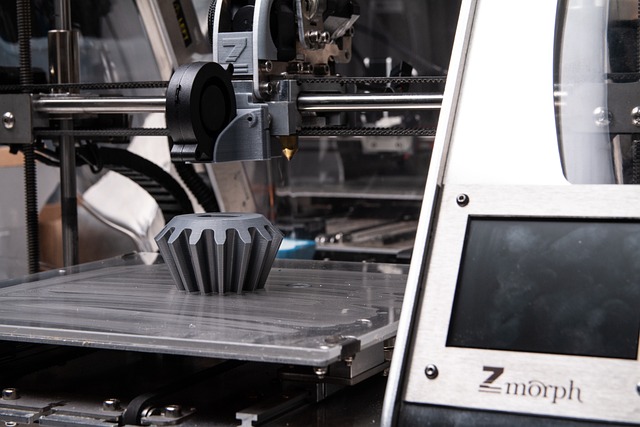

At their core, 3D printers operate on a simple principle called additive manufacturing. Unlike traditional manufacturing that cuts away material (subtractive manufacturing), 3D printers build objects by adding material one thin layer at a time. The process begins with a digital 3D model, typically created using Computer-Aided Design (CAD) software or obtained from online repositories. This model is then sliced into hundreds or thousands of horizontal layers using specialized software.

During printing, the machine follows these layer instructions precisely, depositing material according to each cross-sectional slice. The printer head moves along X and Y axes while the build platform adjusts on the Z-axis, allowing for three-dimensional construction. Depending on the technology, the printer might use extrusion, light curing, powder binding, or other methods to solidify materials into the desired shape. After printing completes, many objects require post-processing steps like removing support structures, curing, or surface finishing.

Different Types of 3D Printing Technologies

Several distinct 3D printing technologies have emerged, each with unique advantages for specific applications:

Fused Deposition Modeling (FDM) is the most common and affordable technology, where thermoplastic filament is heated and extruded through a nozzle to build objects layer by layer. FDM printers are widely used by hobbyists, schools, and for basic prototyping due to their accessibility and relatively low material costs.

Stereolithography (SLA) uses a laser to cure liquid photopolymer resin into hardened plastic. SLA printers produce exceptionally smooth, detailed parts with superior surface finish, making them ideal for jewelry, dental applications, and high-detail prototypes.

Selective Laser Sintering (SLS) fuses powder materials using a high-powered laser, allowing for complex geometries without support structures. This technology excels in industrial applications, creating durable parts from nylon, metal, ceramic, or glass powders.

Digital Light Processing (DLP) is similar to SLA but uses a digital light projector to cure entire layers at once, offering faster print speeds for certain applications. Other technologies include Material Jetting, Binder Jetting, and Direct Metal Laser Sintering (DMLS), each serving specialized industrial needs.

Applications and Uses for 3D Printing

The versatility of 3D printing has led to its adoption across numerous industries and fields:

In manufacturing, companies use 3D printing for rapid prototyping, creating functional parts, and producing customized components that would be difficult or impossible with traditional methods. The automotive and aerospace industries utilize the technology for lightweight parts with complex geometries.

Healthcare has embraced 3D printing for patient-specific anatomical models, surgical guides, dental appliances, prosthetics, and even bioprinting of tissues. These applications improve surgical outcomes and patient care through customization.

Education institutions implement 3D printing to enhance STEM learning, allowing students to bring designs to life and understand spatial concepts through hands-on experience. Architecture firms create detailed scale models of buildings and landscapes, while product designers rapidly iterate through prototypes.

For hobbyists and makers, 3D printers enable personal manufacturing of replacement parts, custom figurines, home décor, and creative projects limited only by imagination.

Materials Used in 3D Printing

The range of printable materials has expanded dramatically, offering options for virtually every application:

Thermoplastics remain the most common materials, with options like PLA (Polylactic Acid), a biodegradable material ideal for beginners; ABS (Acrylonitrile Butadiene Styrene), known for durability and heat resistance; PETG, which combines strength with ease of printing; and specialty filaments infused with wood, metal, carbon fiber, or flexible properties.

Resins used in SLA and DLP printing offer exceptional detail and surface finish, with specialized formulations for dental work, jewelry casting, engineering applications, and biocompatible medical uses.

Metal printing, while primarily industrial, enables production of complex parts in aluminum, titanium, stainless steel, and precious metals. Ceramic printing produces items for both artistic and functional applications, while advanced materials like graphene and custom composites push the boundaries of what’s possible.

Choosing the Right 3D Printer

Selecting an appropriate 3D printer depends on your specific needs, technical expertise, and budget. Consumer-grade FDM printers start around $200 for basic models, while professional and industrial systems can cost tens or hundreds of thousands of dollars. When evaluating options, consider:

Build volume determines the maximum size of printable objects. Larger volumes allow for bigger prints but typically come with higher price tags and larger physical footprints.

Print resolution affects detail quality, with layer heights ranging from 0.1mm to 0.4mm on most consumer printers. Resolution requirements depend on your application – functional prototypes may not need the fine detail required for display models or precision parts.

Print speed, reliability, and ease of use vary significantly between models. Beginners may prioritize user-friendly interfaces and reliable operation, while experienced users might prefer customizable settings and higher speeds.

| Printer Type | Typical Price Range | Best For | Key Considerations |

|---|---|---|---|

| Entry-Level FDM | $200-$500 | Beginners, Hobbyists | Smaller build volume, Basic materials |

| Mid-Range FDM | $500-$1,500 | Enthusiasts, Small Businesses | Better reliability, Larger build volume |

| Prosumer FDM | $1,500-$4,000 | Small Production, Professional Use | Enclosed chambers, Multiple materials |

| Desktop SLA/DLP | $300-$3,000 | Detailed Models, Jewelry | Smaller build volume, Resin handling |

| Professional SLA | $3,000-$10,000 | Dental, Precision Parts | Higher accuracy, Specialized resins |

| Industrial Systems | $10,000-$100,000+ | Manufacturing, Medical | Large volume, Advanced materials |

Prices, rates, or cost estimates mentioned in this article are based on the latest available information but may change over time. Independent research is advised before making financial decisions.

Maintenance and Operational Considerations

Owning and operating a 3D printer requires ongoing maintenance and understanding of operational factors. Regular calibration ensures print quality, while proper bed leveling prevents common printing issues. Different materials may require specific print temperatures, cooling settings, and environmental conditions for optimal results.

Consumables represent an ongoing cost beyond the initial printer purchase. Filament for FDM printers typically costs $20-$50 per kilogram, while specialty filaments and resins can cost significantly more. Print failures, though decreasing with improved technology, still occur and contribute to material waste.

Safety considerations include proper ventilation, especially when printing with materials that emit potentially harmful particles or fumes. Enclosed printing chambers, air filtration systems, and proper workshop ventilation help mitigate these concerns. Additionally, users should be aware of the mechanical and thermal risks associated with moving parts and hot components.

As 3D printing technology continues to evolve, we’re seeing faster print speeds, larger build volumes, multi-material capabilities, and increasingly sophisticated software integration. These advancements are making the technology more accessible while simultaneously expanding its capabilities for professional and industrial applications, ensuring 3D printing will remain at the forefront of digital manufacturing for years to come.