Understanding 3D Printers: Technology, Applications, and Considerations

3D printing technology has revolutionized manufacturing across industries by enabling the creation of three-dimensional objects from digital models. This additive manufacturing process builds objects layer by layer, offering unprecedented design freedom, reduced waste, and the ability to produce complex geometries that traditional manufacturing methods cannot achieve. From rapid prototyping to customized production, 3D printers have transformed how we conceptualize, design, and create physical objects.

How 3D Printers Work

3D printers operate on the principle of additive manufacturing, building objects by adding material one layer at a time. The process begins with a digital 3D model, typically created using Computer-Aided Design (CAD) software or obtained from 3D scanning. This digital blueprint is then processed by slicing software that converts the model into thin horizontal layers and generates instructions for the printer to follow.

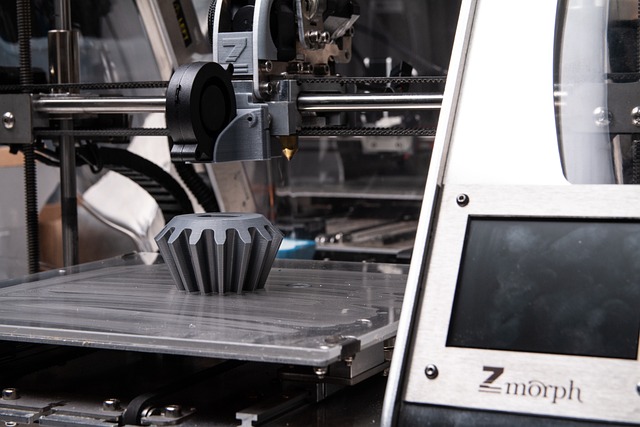

The printing process varies depending on the technology used. Fused Deposition Modeling (FDM), the most common technology for consumer printers, works by extruding thermoplastic filament through a heated nozzle that moves along predetermined paths to create each layer. Other technologies include Stereolithography (SLA), which uses light to cure liquid resin; Selective Laser Sintering (SLS), which fuses powder materials with a laser; and Digital Light Processing (DLP), which projects light onto photosensitive resin.

Types of 3D Printers for Different Applications

3D printers come in various forms, each designed for specific applications and materials. Desktop FDM printers are popular among hobbyists and small businesses due to their affordability and ease of use. These machines typically work with thermoplastics like PLA, ABS, PETG, and flexible filaments, making them suitable for prototyping, educational purposes, and small-scale production.

Industrial 3D printers offer higher precision, larger build volumes, and the ability to work with advanced materials. SLS printers can produce durable nylon parts, while metal 3D printers use technologies like Direct Metal Laser Sintering (DMLS) or Electron Beam Melting (EBM) to create functional metal components. In healthcare, specialized bioprinters can produce tissue-like structures using living cells, while construction industry printers can extrude concrete to build architectural elements.

Materials Used in 3D Printing

The range of materials available for 3D printing continues to expand, offering diverse properties to suit various applications. Thermoplastics remain the most widely used materials, with PLA (Polylactic Acid) valued for its biodegradability and ease of printing, and ABS (Acrylonitrile Butadiene Styrene) known for its durability and heat resistance. PETG combines the ease of printing of PLA with improved durability, while TPU (Thermoplastic Polyurethane) offers flexibility for applications requiring elasticity.

Beyond plastics, modern printers can work with resins, metals, ceramics, composites, and even food ingredients. Metal printing enables the production of complex parts for aerospace, automotive, and medical applications. Composite materials that combine plastics with wood, carbon fiber, or glass provide enhanced mechanical properties. The continuous development of new printing materials is expanding the potential applications of 3D printing technology.

Industries Transformed by 3D Printing

3D printing has made significant inroads across numerous industries. In manufacturing, it enables rapid prototyping, reducing product development cycles from months to days. The technology allows engineers to quickly iterate designs, test functionality, and refine products before committing to mass production. For small-batch manufacturing, 3D printing eliminates the need for expensive tooling, making customized production economically viable.

In healthcare, 3D printers produce patient-specific anatomical models for surgical planning, custom prosthetics, and dental appliances. The aerospace industry uses the technology to create lightweight components with complex internal structures that reduce weight while maintaining strength. Architecture firms print detailed models of buildings, while the fashion industry experiments with printed textiles and accessories. Education institutions employ 3D printers to enhance STEM learning by allowing students to design and create physical objects.

Cost Considerations for 3D Printing Technology

The cost of 3D printing equipment varies widely based on technology, capabilities, and intended use. Entry-level desktop FDM printers for hobbyists and beginners are available from €200 to €500, while prosumer models with larger build volumes and better reliability range from €500 to €3,000. Professional-grade printers with enhanced precision and material capabilities typically cost between €3,000 and €10,000. Industrial systems for production environments can range from €10,000 to over €500,000 for metal printing systems.

| Printer Type | Representative Models | Price Range | Key Features |

|---|---|---|---|

| Entry-Level FDM | Creality Ender 3, Anycubic i3 Mega | €200-€500 | DIY kits, basic features, smaller build volume |

| Mid-Range FDM | Prusa i3 MK3S+, Ultimaker 2+ | €750-€2,500 | Reliability, better quality, auto-leveling |

| Professional FDM | Ultimaker S5, Raise3D Pro2 | €3,000-€6,000 | Dual extrusion, enclosed chamber, larger build volume |

| Resin (SLA/DLP) | Elegoo Mars, Formlabs Form 3 | €250-€3,500 | High detail, smooth surfaces, smaller build volume |

| Industrial SLS | EOS P396, 3D Systems ProX | €80,000-€300,000 | Production-grade parts, advanced materials |

Prices, rates, or cost estimates mentioned in this article are based on the latest available information but may change over time. Independent research is advised before making financial decisions.

Beyond the initial printer investment, ongoing costs include materials (€20-€50 per kilogram for standard filaments, €150-€400 for specialty materials), maintenance (replacement parts, nozzles), and software (from free open-source options to subscription-based professional packages). Energy consumption, post-processing equipment, and potential failed prints also contribute to the total cost of ownership.

Future Trends in 3D Printing Technology

The future of 3D printing promises exciting developments across multiple fronts. Speed improvements are addressing one of the technology’s primary limitations, with new techniques like Continuous Liquid Interface Production (CLIP) dramatically reducing print times. Material science advancements are expanding the range of printable substances, including multi-material printing that combines different properties within a single print job.

Larger build volumes are enabling the printing of bigger objects, while improved resolution and surface finish are enhancing the quality of printed parts. Automation and artificial intelligence are streamlining the printing process, from design optimization to quality control. Distributed manufacturing networks that connect printers across locations are emerging, potentially transforming global supply chains by enabling on-demand, localized production.

As 3D printing continues to mature, it’s becoming increasingly integrated with other manufacturing technologies in hybrid production systems. The convergence of 3D printing with robotics, IoT, and advanced materials is opening new possibilities for innovation across industries. While challenges remain in terms of standards, certification, and intellectual property protection, the technology’s trajectory points toward more accessible, capable, and versatile printing solutions in the coming years.