Product Safety Through Comprehensive Equipment Testing

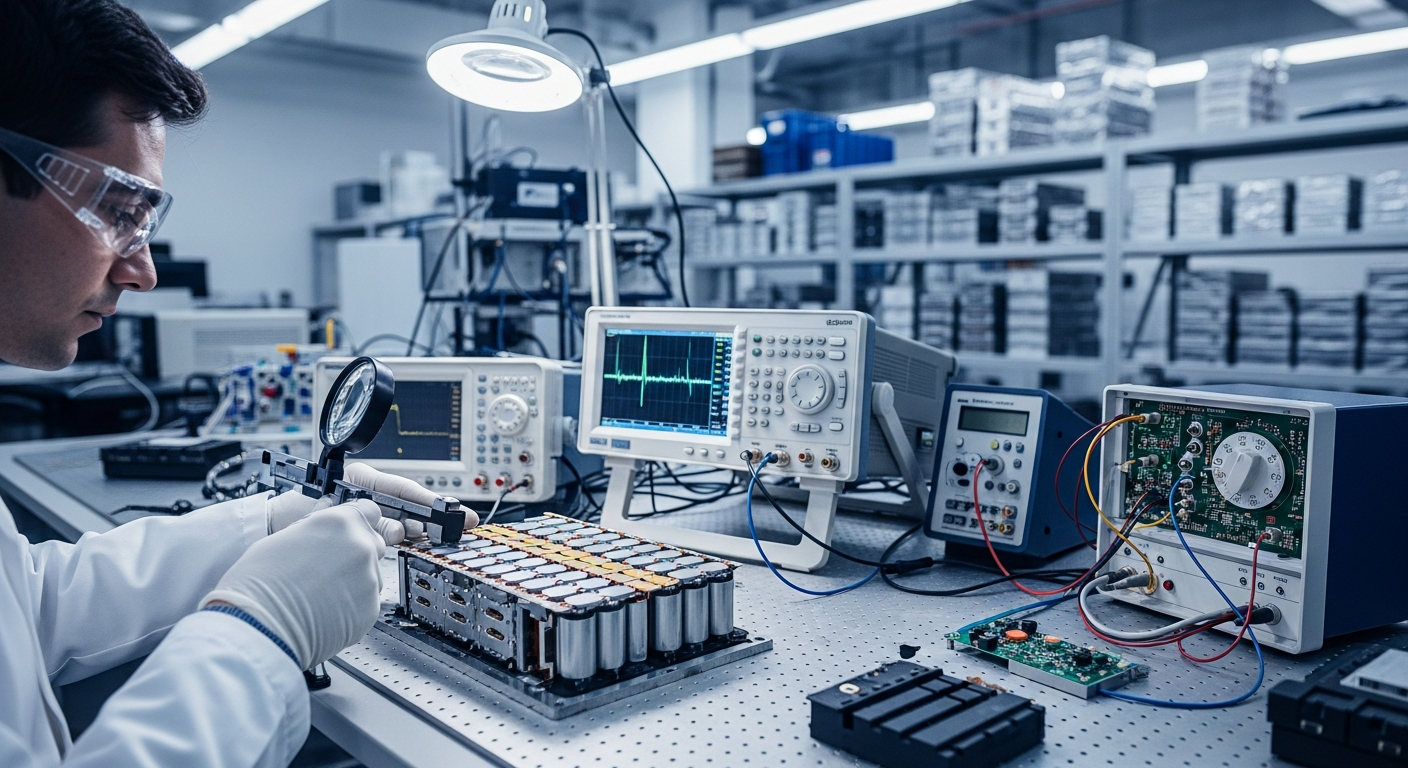

Equipment testing serves as the foundation of product safety, ensuring that devices and systems meet rigorous standards before reaching consumers. From electronic components to industrial machinery, comprehensive testing protocols identify potential hazards, verify performance specifications, and guarantee reliability throughout a product's lifecycle. This systematic approach protects both manufacturers and end-users while maintaining quality standards across industries.

Modern manufacturing relies heavily on systematic testing procedures to ensure product safety and reliability. Equipment testing encompasses various methodologies designed to evaluate performance, identify defects, and verify compliance with industry standards. These processes form the backbone of quality assurance in manufacturing environments worldwide.

How Equipment Testing Keeps Products Safe, Reliable, and Ready

Equipment testing involves subjecting products to controlled conditions that simulate real-world usage scenarios. This process includes stress testing, environmental exposure, electrical safety verification, and functional performance evaluation. Testing laboratories utilize specialized equipment to measure parameters such as temperature resistance, electrical conductivity, mechanical strength, and electromagnetic compatibility. These assessments help identify potential failure points before products reach market, preventing safety incidents and costly recalls.

The testing process typically follows established protocols from organizations like ANSI, IEEE, and IEC. These standards define specific requirements for different product categories, ensuring consistent evaluation criteria across the industry. Testing procedures may include accelerated aging tests, vibration analysis, thermal cycling, and chemical resistance evaluation.

Why Equipment Testing Matters

The importance of equipment testing extends beyond basic safety compliance. Proper testing reduces liability risks for manufacturers, builds consumer confidence, and supports regulatory approval processes. Companies that invest in comprehensive testing programs often experience fewer warranty claims, improved brand reputation, and enhanced market competitiveness.

Testing also enables continuous improvement in product design. Data collected during testing phases provides valuable insights into material performance, design weaknesses, and optimization opportunities. This information drives innovation and helps engineers develop more robust, efficient products.

Regulatory bodies worldwide require specific testing certifications for various product categories. Medical devices, automotive components, consumer electronics, and industrial equipment must all undergo rigorous testing to meet safety standards. Failure to comply with these requirements can result in market exclusion, legal penalties, and significant financial losses.

Electronic Test Equipment Insights

Electronic test equipment represents a specialized category of testing tools designed to evaluate electrical and electronic systems. These instruments include oscilloscopes, spectrum analyzers, multimeters, signal generators, and network analyzers. Each tool serves specific purposes in measuring electrical parameters and identifying performance issues.

Modern electronic test equipment often incorporates advanced features such as automated testing sequences, data logging capabilities, and remote monitoring functions. These capabilities enable more efficient testing processes and provide detailed documentation for compliance purposes. Many instruments now offer software integration, allowing seamless data transfer and analysis.

The selection of appropriate test equipment depends on the specific requirements of the product being evaluated. High-frequency applications may require specialized RF test equipment, while power systems need instruments capable of handling high voltages and currents safely.

| Equipment Type | Provider | Cost Estimation |

|---|---|---|

| Basic Multimeter | Fluke, Keysight | $200 - $800 |

| Oscilloscope | Tektronix, Rigol | $1,000 - $15,000 |

| Spectrum Analyzer | Rohde & Schwarz, Anritsu | $5,000 - $50,000 |

| Environmental Chamber | Thermotron, ESPEC | $15,000 - $100,000 |

| Universal Testing Machine | Instron, MTS | $25,000 - $200,000 |

Prices, rates, or cost estimates mentioned in this article are based on the latest available information but may change over time. Independent research is advised before making financial decisions.

Testing Standards and Compliance

International testing standards provide frameworks for consistent evaluation procedures across different industries and regions. ISO 9001 quality management systems incorporate testing requirements as part of overall quality assurance processes. Product-specific standards such as UL for electrical safety, FCC for electromagnetic compatibility, and FDA regulations for medical devices establish detailed testing protocols.

Compliance with these standards often requires third-party testing and certification. Accredited testing laboratories provide independent verification of product performance and safety characteristics. This third-party validation adds credibility to manufacturer claims and facilitates market acceptance.

Future Trends in Equipment Testing

The testing industry continues evolving with technological advances and changing market demands. Artificial intelligence and machine learning algorithms increasingly support automated testing processes, improving efficiency and accuracy. Remote testing capabilities enable distributed teams to collaborate on testing programs, while cloud-based data management systems provide better access to testing results and historical data.

Sustainability considerations also influence testing practices, with increased focus on environmental impact assessment and lifecycle analysis. These trends reflect growing awareness of environmental responsibility and regulatory requirements for sustainable product development.

Equipment testing remains essential for maintaining product safety, reliability, and market competitiveness. As technology advances and regulatory requirements evolve, testing methodologies will continue adapting to meet new challenges while maintaining the fundamental goal of protecting consumers and ensuring product quality.