Green vs Blue vs Red Wavelengths for Non-Contact Marking

Selecting a laser wavelength shapes how cleanly, quickly, and consistently you can mark metals, plastics, glass, and ceramics. For manufacturers in Kenya, matching green, blue, or red light to material absorption, part geometry, and available local service support can improve uptime, contrast, and overall quality.

Non-contact marking depends on how a material absorbs light at different wavelengths. Green, blue, and red each interact differently with metals and polymers, resulting in varied marking contrast, heat input, and speed. Understanding these fundamentals—and pairing them with credible suppliers and regional support—helps teams in Kenya deploy robust, compliant systems for traceability, branding, and component identification.

Comparing green, blue, and red laser power

Green lasers at 532 nm are popular for marking reflective or delicate materials because many metals and some plastics absorb green better than near‑infrared. They can deliver fine spots and controlled heat input, enabling crisp, shallow marks with limited discoloration. Blue lasers around 445–460 nm greatly improve coupling into highly reflective metals like copper and gold, making them attractive for electrical conductors, busbars, and battery components. Red light (typically 635–660 nm) is less common for industrial marking; many metals and clear plastics absorb it poorly, so red sources are usually reserved for alignment or very specific polymer color‑change applications with additives.

In practice, wavelength choice and power must align with marking mechanisms: ablation (removing a thin layer), annealing (surface oxidation on steel), foaming/color change (polymers), and carbonization (organics). Green and blue often achieve higher contrast on challenging metals at lower energy, reducing burrs and heat‑affected zones. While the phrase Understanding Laser Technology: Comparing Green, Blue, and Red Laser Power is often framed around raw wattage, beam quality (M²), pulse width (ns/ps/fs), and repetition rate matter just as much. A well‑controlled pulsed green source can outperform a higher‑watt continuous blue module for fine text, micro‑codes, or QR patterns, depending on the substrate and mark depth target.

Choosing a supplier for high‑power devices

How To Choose The Right Laser Supplier For High-Power Devices is ultimately about reliability and lifecycle costs rather than headline wattage. In Kenya, evaluate whether the supplier provides: (1) material‑specific application testing with documented parameters; (2) evidence of compliance with IEC 60825 and relevant electrical standards; (3) an enclosure with interlocks, fume extraction, and OD‑rated eyewear matched to the chosen wavelength; and (4) regional after‑sales support—directly or via trained partners—for installation, operator training, and spare parts. Ask for uptime commitments, preventive maintenance schedules, and replacement lead times. Confirm that the power rating is measured at the workpiece (after beam delivery), not only at the source, and that beam stability and pointing are characterized over ambient temperature ranges typical in Kenyan workshops.

Reliable wholesale laser suppliers

Beyond Retail: A Guide To Finding Reliable Wholesale Laser Suppliers begins with verification of the manufacturer–reseller relationship. Request OEM authorization letters, serial‑number traceability, and warranty coverage terms that apply in your area. For wholesale purchases, insist on a sample‑marking report using your actual parts, including microscope images, surface roughness (Ra) where relevant, and parameter logs (power, pulse width, frequency, scan speed, focus). Review import documentation, KEBS requirements, and Incoterms that define who handles insurance and transport risk. Consider availability of consumables such as fume filters and protective windows, and check that replacement optics and diodes are stocked by the wholesaler or their regional partners.

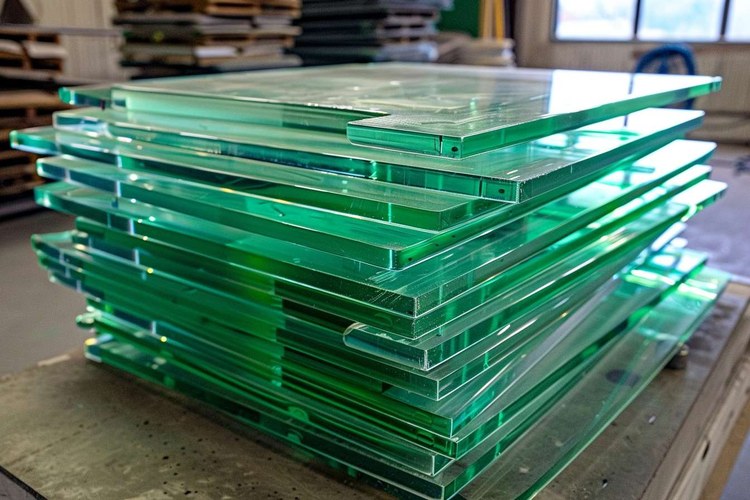

Representative wavelength guidance for common materials: stainless steel often marks well with green via annealing for dark, legible results; copper and other highly reflective conductors typically benefit from blue for stable absorption; many dark plastics respond to green or near‑IR via foaming or color change; glass and ceramics can be marked with green when surface micro‑cracking must be minimized, though specialized UV sources may outperform both for fine detail. Always validate on your parts, as coatings, fillers, and surface finish shift absorption.

The following real‑world products illustrate how providers position solutions across wavelengths for marking and light materials processing.

| Product/Service Name | Provider | Key Features |

|---|---|---|

| TruMark 6330 (532 nm) | TRUMPF | Pulsed green marking system; good absorption on reflective metals; integrated scanner and vision options |

| AVIA 532 DPSS | Coherent | Industrial 532 nm DPSS source; short pulses and good beam quality for fine ablation and polymer color change |

| HighLight FL-Blue | Coherent | High‑power 450 nm blue modules; strong coupling to copper; available with beam delivery for scanning applications |

| AO‑150 Blue Diode Laser | NUBURU | 450 nm class system optimized for copper and precious metals; supports high‑contrast marks with tuned parameters |

| LuxX 660 nm Module | Omicron Laserage | 660 nm red diode module; niche use for polymer color‑change with absorbers; commonly used as alignment aid |

Note that specific configurations vary; confirm marking suitability, safety class, and integration options with the manufacturer.

In Kenya, practical deployment considerations include stable power (conditioning or UPS for sensitive electronics), dust and humidity control in enclosures, and consistent fixturing so focal distance and spot size remain reproducible. Plan for fume extraction tailored to your substrate—metal fumes differ from polymer off‑gassing—and ensure filters are replaced on schedule. For traceability, verify that your marking software exports parameter recipes and audit logs compatible with your quality system.

Conclusion: For non‑contact marking, green and blue wavelengths cover most metal and mixed‑material scenarios with efficient absorption and controlled heat input, while red is reserved for niche polymer tasks or alignment. Matching wavelength and pulse format to your material, then selecting a supplier that can demonstrate results, safety, and support in your area, will deliver consistent, legible marks with fewer process variables and better long‑term uptime.