Equipment Testing Protocols for Consumer Safety Standards

Consumer safety depends on rigorous equipment testing protocols that evaluate everything from household appliances to electronic devices before they reach store shelves. These comprehensive testing procedures ensure products meet strict safety standards, perform reliably under normal use conditions, and protect users from potential hazards. Understanding how these protocols work helps consumers make informed purchasing decisions while appreciating the complex safety measures that protect families and businesses across America.

How Equipment Testing Keeps Products Safe, Reliable, and Ready

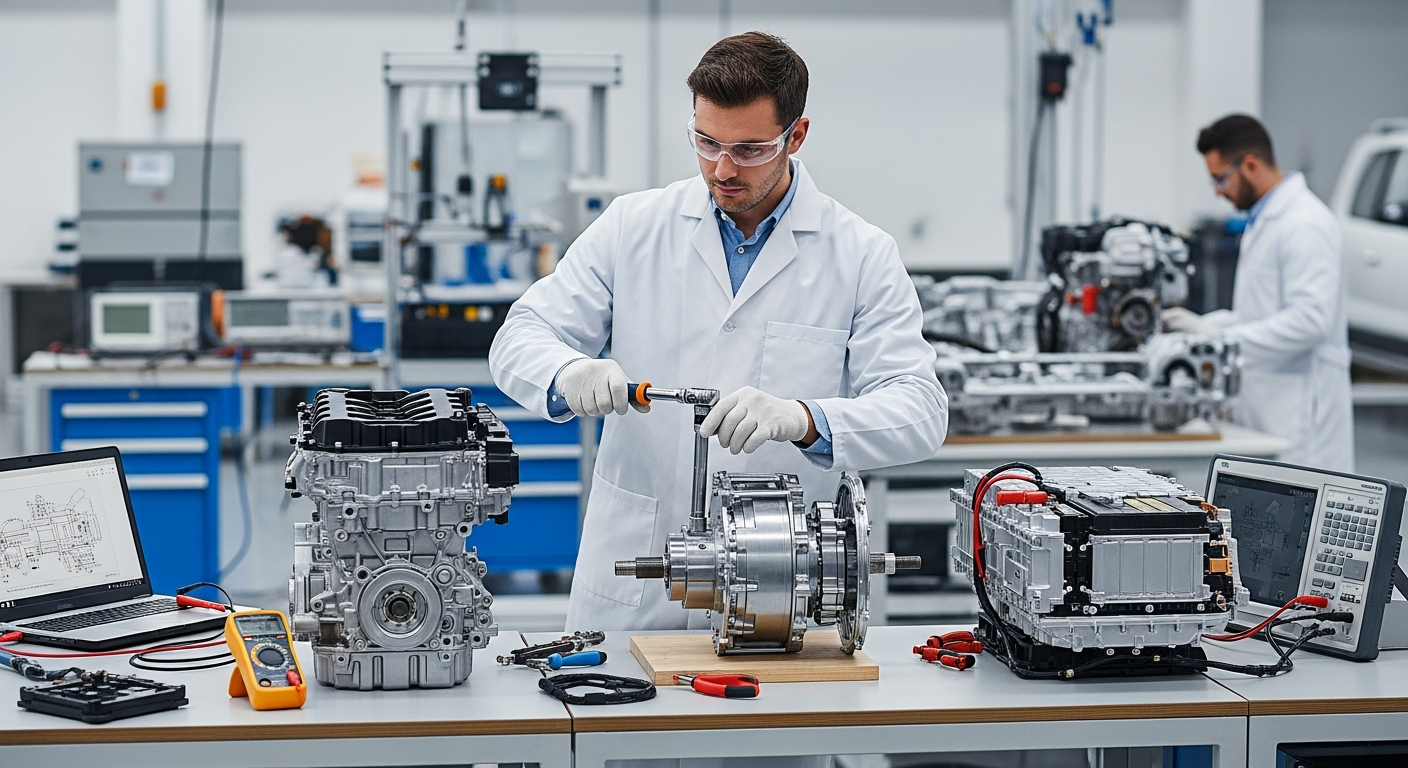

Equipment testing serves as the critical barrier between potentially dangerous products and consumer markets. Testing laboratories subject products to extreme conditions, simulating years of normal use within weeks or months. This process identifies potential failures, safety hazards, and performance issues before products reach consumers.

Testing protocols vary by product category but typically include electrical safety evaluations, mechanical stress tests, environmental exposure assessments, and electromagnetic compatibility checks. Products must pass multiple rounds of testing, often requiring modifications and retesting until they meet all applicable safety standards.

The testing process also evaluates user interfaces, warning labels, and instruction manuals to ensure consumers can operate products safely. This comprehensive approach significantly reduces the likelihood of accidents, injuries, or property damage once products enter the marketplace.

Get Insights on Electronic Test Equipment

Electronic test equipment forms the backbone of modern safety testing protocols. Oscilloscopes measure electrical signals and identify potential interference issues, while multimeters verify voltage, current, and resistance values across different operating conditions. Spectrum analyzers detect electromagnetic emissions that could interfere with other devices or exceed regulatory limits.

Advanced testing equipment includes environmental chambers that simulate extreme temperatures, humidity levels, and atmospheric conditions. Vibration tables replicate transportation stresses and normal use patterns, while salt spray chambers test corrosion resistance for products exposed to harsh environments.

Automated testing systems now handle repetitive evaluations, ensuring consistent results while reducing human error. These systems can run continuous tests for thousands of hours, collecting data that would be impossible to gather through manual testing methods.

Why Equipment Testing Matters

Equipment testing directly impacts public safety, product reliability, and manufacturer liability. Products that fail in the field can cause injuries, property damage, and expensive recalls that damage brand reputation. Thorough testing prevents these outcomes by identifying problems during development rather than after market release.

Regulatory agencies like the Consumer Product Safety Commission require testing for many product categories. Manufacturers who skip proper testing face potential lawsuits, regulatory penalties, and market exclusion. Insurance companies also consider testing records when evaluating coverage and claims.

Testing also drives innovation by revealing performance limitations and improvement opportunities. Engineers use test results to refine designs, select better materials, and optimize manufacturing processes. This continuous improvement cycle benefits both manufacturers and consumers through safer, more reliable products.

| Testing Laboratory | Services Offered | Specialization Areas |

|---|---|---|

| Underwriters Laboratories | Safety certification, performance testing | Electronics, appliances, industrial equipment |

| Intertek | Product testing, certification, inspection | Consumer goods, automotive, medical devices |

| SGS | Testing, inspection, certification | Electronics, toys, textiles, chemicals |

| TÜV Rheinland | Safety testing, quality assurance | Automotive, industrial, renewable energy |

| Bureau Veritas | Testing, inspection, certification | Marine, oil and gas, consumer products |

Testing costs vary significantly based on product complexity, required certifications, and testing duration. Basic electrical safety testing might cost several thousand dollars, while comprehensive certification for complex electronics can exceed fifty thousand dollars. Manufacturers typically budget two to five percent of development costs for testing and certification.

The investment in proper testing pays dividends through reduced liability exposure, faster market acceptance, and improved product quality. Products with recognized safety certifications often command premium prices and gain easier access to retail channels.

Consumers benefit from this testing infrastructure through access to safer, more reliable products. Understanding these protocols helps buyers recognize quality indicators like UL listings, CE marks, and FCC compliance statements that signal proper testing and certification.

Equipment testing protocols represent a critical investment in consumer safety and product quality. These comprehensive evaluations protect users while enabling manufacturers to deliver innovative products with confidence. As technology advances, testing methods continue evolving to address new safety challenges and maintain the high standards American consumers expect and deserve.