Customizable Housing Units Redefine Building Efficiency

The housing industry is experiencing a revolutionary shift toward modular construction methods that prioritize speed, sustainability, and customization. These factory-built housing units are assembled off-site in controlled environments before being transported to their final locations, offering homeowners unprecedented flexibility in design while significantly reducing construction timelines. This innovative approach to homebuilding combines traditional craftsmanship with modern manufacturing techniques, creating structures that meet contemporary living standards while addressing the growing demand for efficient, affordable housing solutions.

The Future of Housing with Fast, Customizable Construction

Modular construction represents a paradigm shift in how we approach residential building projects. Unlike traditional stick-built homes, these structures are manufactured in specialized facilities where weather delays, material theft, and site-related complications are virtually eliminated. The controlled environment allows for precise quality control measures and consistent building standards that often exceed those of conventional construction methods.

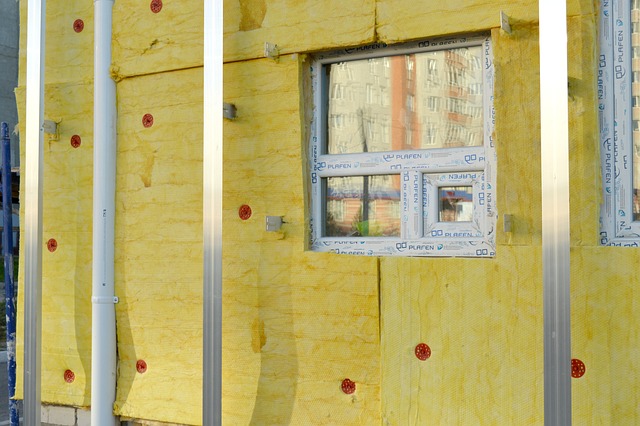

The manufacturing process involves creating individual sections or modules in a factory setting, complete with electrical systems, plumbing, insulation, and interior finishes. These modules are then transported to the building site and assembled using cranes and specialized equipment. This method can reduce overall construction time by 30-50% compared to traditional building approaches.

Understanding Modular Construction Systems

Modern modular systems utilize advanced engineering and design software to create highly customizable floor plans and architectural features. Homeowners can select from various module configurations, exterior materials, interior finishes, and energy-efficient upgrades. The flexibility extends to both single-family homes and multi-story residential complexes.

The structural integrity of these homes meets or exceeds traditional building codes, with many manufacturers incorporating enhanced features like reinforced connections between modules and upgraded insulation systems. The transportation requirements actually necessitate stronger construction methods, resulting in buildings that can withstand significant structural stresses.

Cost Analysis and Market Comparison

The financial advantages of modular construction stem from reduced labor costs, shorter construction timelines, and minimized weather-related delays. Factory production allows for bulk purchasing of materials and streamlined labor processes that translate into cost savings for consumers.

| Provider | Construction Type | Cost Per Square Foot | Timeline |

|---|---|---|---|

| Clayton Homes | Single/Multi-section | $50-$120 | 4-6 weeks |

| Westchester Modular | Custom Modular | $80-$150 | 6-8 weeks |

| Method Homes | Prefab Modular | $150-$400 | 8-12 weeks |

| Champion Home Builders | Manufactured/Modular | $45-$95 | 3-5 weeks |

| Blu Homes | Steel Frame Modular | $200-$500 | 10-16 weeks |

Prices, rates, or cost estimates mentioned in this article are based on the latest available information but may change over time. Independent research is advised before making financial decisions.

Environmental Benefits and Sustainability

Factory-based construction significantly reduces material waste through precise cutting and optimized material usage. Many manufacturers report waste reduction of up to 90% compared to traditional construction sites. The controlled environment also allows for better recycling programs and material recovery systems.

Energy efficiency is often superior in modular homes due to tighter construction tolerances and advanced insulation techniques. Many units incorporate sustainable materials, energy-efficient appliances, and renewable energy systems like solar panels as standard or optional features.

Quality Control and Building Standards

The factory environment enables comprehensive quality inspections at multiple stages of construction. Each module undergoes structural, electrical, and plumbing inspections before leaving the manufacturing facility. This multi-point inspection process often results in fewer defects and warranty claims compared to site-built homes.

Building codes for modular homes are identical to those for traditional construction, with additional requirements for transportation and assembly. Many manufacturers exceed minimum code requirements to ensure structural integrity during transport and installation.

Installation and Site Preparation

Site preparation for modular homes involves creating proper foundations, utility connections, and access routes for delivery trucks and cranes. The foundation requirements are similar to traditional homes, including full basements, crawl spaces, or slab-on-grade options.

The installation process typically requires 1-3 days for module placement and several additional weeks for final connections, exterior finishing, and site work. Local building inspectors verify proper installation and code compliance before issuing occupancy permits.

Modular construction continues to gain acceptance among homeowners, builders, and financial institutions as manufacturing techniques improve and design options expand. The combination of reduced construction time, consistent quality, and customization possibilities positions this building method as a viable solution for addressing contemporary housing needs while maintaining cost-effectiveness and environmental responsibility.