A Comprehensive Guide to Modern Printing Technology

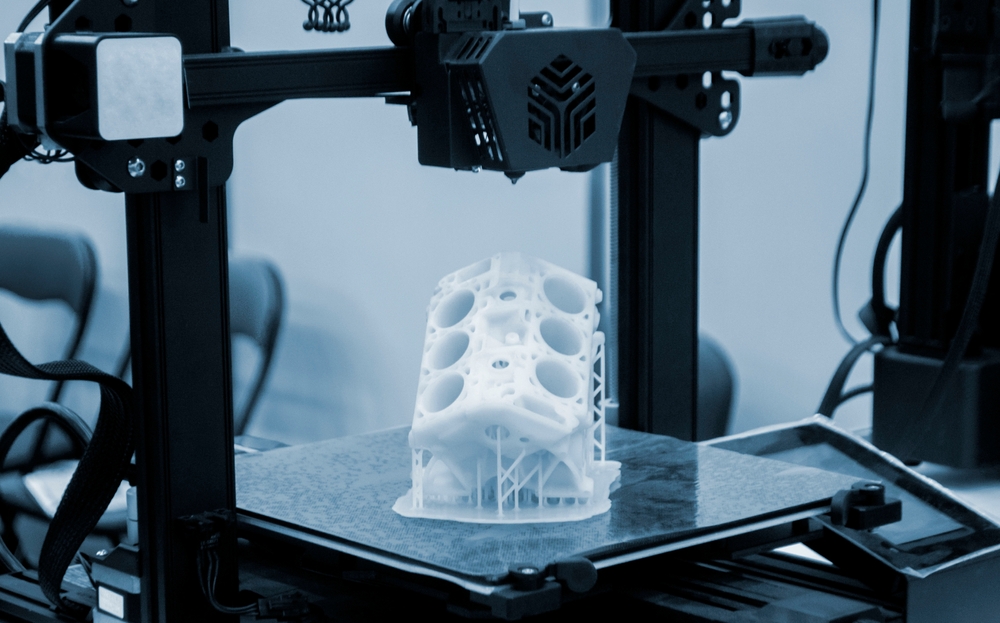

3D printing technology has revolutionized manufacturing, prototyping, and creative production across multiple industries. This innovative technology allows users to transform digital designs into physical objects layer by layer, opening up possibilities for customization and production that were previously impossible with traditional manufacturing methods.

3D printing has transformed how we think about manufacturing and creation. By building objects layer by layer from digital designs, these remarkable machines have democratized production capabilities that were once available only to large industries. From hobbyists creating custom figurines to medical professionals printing prosthetics, 3D printers have found applications across countless fields, changing how we approach design, prototyping, and small-scale manufacturing.

How 3D Printers Work

3D printers operate on a surprisingly straightforward principle: additive manufacturing. Unlike traditional manufacturing that cuts away material (subtractive manufacturing), 3D printers build objects by depositing material layer by layer according to a digital blueprint. The process begins with a 3D model created using Computer-Aided Design (CAD) software. This model is then sliced into hundreds or thousands of horizontal layers by specialized software. The printer reads this data and systematically builds each layer, fusing them together to create the final three-dimensional object.

Most consumer 3D printers use a technology called Fused Deposition Modeling (FDM), where a plastic filament is heated and extruded through a nozzle that moves precisely to create each layer. However, other technologies like Stereolithography (SLA) use light to cure liquid resin, while Selective Laser Sintering (SLS) uses lasers to fuse powder materials together.

Types of 3D Printers for Different Applications

The 3D printer market offers diverse technologies suited to different needs, budgets, and applications. FDM printers are the most common and affordable option for home users and small businesses, typically costing between €200 and €1,000. These machines are excellent for prototyping, hobbyist projects, and educational purposes.

For higher precision and smoother surface finishes, SLA printers use liquid resin cured by light to create detailed models. These are particularly popular in jewelry design, dentistry, and creating detailed miniatures. SLS printers, which use lasers to fuse powder materials, are primarily used in industrial settings for functional parts with complex geometries.

Metal 3D printers, though significantly more expensive, have revolutionized manufacturing by enabling the creation of complex metal parts that would be impossible or prohibitively expensive to produce with traditional methods. These machines are transforming industries from aerospace to medical device manufacturing.

Materials Used in 3D Printing

The versatility of 3D printing extends to the wide range of materials available. The most common materials for FDM printers are thermoplastics like PLA (Polylactic Acid), which is biodegradable and derived from renewable resources like corn starch. ABS (Acrylonitrile Butadiene Styrene) offers greater durability but requires higher printing temperatures and can produce fumes during printing.

More specialized materials include PETG, which combines ease of printing with durability; TPU, a flexible filament for creating bendable objects; and composite filaments that blend plastic with wood, metal, carbon fiber, or other materials to create unique properties and appearances.

Resin printers use photopolymer resins that come in various formulations, including standard, tough, flexible, dental, and castable varieties. Industrial printers can work with an even broader range of materials, including various metals, ceramics, and even biological materials for medical applications.

Applications of 3D Printing Technology

The applications of 3D printing span virtually every industry. In healthcare, 3D printers create customized prosthetics, surgical guides, and even experimental human tissues. Architects use 3D printers to rapidly produce detailed models of buildings and landscapes. The automotive and aerospace industries employ 3D printing for prototyping and manufacturing lightweight, complex parts that reduce weight and improve performance.

Education has embraced 3D printing as a powerful teaching tool that allows students to bring their ideas to life and learn principles of design, engineering, and manufacturing. Artists and designers use 3D printing to create unique sculptures, jewelry, and functional art pieces that would be impossible with traditional methods.

In the consumer space, 3D printing enables customization of products from phone cases to home décor items. As the technology continues to advance, we’re seeing more applications in food printing, construction, and even fashion.

Comparison of Popular 3D Printer Models

When choosing a 3D printer, consumers face numerous options across different price points and capabilities. Here’s a comparison of some widely used models:

| Printer Model | Technology | Build Volume | Resolution | Price Range (€) |

|---|---|---|---|---|

| Creality Ender 3 V2 | FDM | 220 x 220 x 250mm | 100 microns | 200-300 |

| Prusa i3 MK3S+ | FDM | 250 x 210 x 210mm | 50 microns | 750-900 |

| Anycubic Photon Mono | SLA | 130 x 80 x 165mm | 50 microns | 250-350 |

| Formlabs Form 3 | SLA | 145 x 145 x 185mm | 25 microns | 3,000-3,500 |

| Ultimaker S5 | FDM | 330 x 240 x 300mm | 20 microns | 5,500-6,500 |

Prices, rates, or cost estimates mentioned in this article are based on the latest available information but may change over time. Independent research is advised before making financial decisions.

Future Trends in 3D Printing

The 3D printing landscape continues to evolve rapidly. Several key trends are shaping the future of this technology. First, we’re seeing dramatic improvements in printing speed, with new technologies promising to reduce print times from hours to minutes. Materials science is also advancing, with researchers developing new filaments and resins with enhanced properties like conductivity, heat resistance, and biodegradability.

Multi-material printing is becoming more accessible, allowing single prints to incorporate different materials with varying properties. This enables the creation of complex objects with moving parts or different textures in a single print job. Size constraints are also being challenged, with large-format printers capable of producing furniture-sized objects or even building components.

Perhaps most exciting is the potential of 3D bioprinting, which uses living cells to create tissue structures. While still experimental, this technology holds promise for creating replacement organs and revolutionizing medical treatments.

As 3D printing technology matures, we can expect continued price reductions, improved user interfaces, and greater integration with other digital fabrication tools. These advancements will further democratize manufacturing and empower individuals and small businesses to create products that previously required industrial facilities.